Safety news

Annual truck and bus brake inspection blitz set for August 21-27, 2022

Create an ergonomic work environment

Does your job require you to stand for long periods? Or maybe you spend hours lifting and pushing heavy materials. Perhaps you’re in an office environment and sit at a desk for hours while typing on a computer most of the day.

These situations are all considered risk factors for musculoskeletal disorders (MSDs). “Musculoskeletal disorders are injuries or disorders of the muscles, nerves, tendons, joints, cartilage, and spinal discs,” according to the National Safety Council (NSC). “They’re disorders that affect the human body’s movement.”

If you’re experiencing symptoms of an MSD, including numbness in the hands or fingers, tingling in your legs, pain, and more, it’s time to perform an ergonomic evaluation of your work environment: your workstation, the equipment and tools you use, and your job tasks. Look for awkward postures; too much sitting or standing in one position; repetitive motions; and exposure to heat, cold, and vibration. Need more information? OSHA has some suggestions and helpful resources.

After you identify your area’s risk factors, work with your supervisor to come up with improvements. Some suggestions from NSC:

- Take stretch breaks.

- Use anti-fatigue mats if you stand for long periods.

- Alternate repetitive tasks with nonrepetitive tasks at regular intervals, and take frequent breaks.

- Place your frequently used tools and materials within easy reach.

- Alternate between tasks that use different muscle groups – if you have to manually stack items, try to switch it up with some sedentary tasks, such as entering shipping data into a computer.

Alcohol, cannabis, prescription drugs, fatigue, and mental distress can all cause impairment in the workplace. “Impairment risks are everyone’s responsibility,” the NSC says.

Stay alert and help keep your workplace safe. Here’s how:

1. Spot the signs. Are you or a co-worker less focused than usual, or acting differently? Consider taking a break or alerting others to evaluate the situation. Don’t jump to conclusions about why someone might be impaired.

2. Start the conversation. If you don’t feel like yourself, assess your reactions and be honest with how you’re feeling. For others, ask how they’re feeling and if they need to take a break. It’s not always easy to have this conversation, but ignoring it could put you or your co-workers at risk.

3. Ask for assistance. If you can’t work safely, ask for assistance from your supervisor or a nearby co-worker. Do the same for any co-workers showing signs of impairment.

4. Know your policies. You can help prevent impairment-related hazards by learning more about your workplace’s policies. Ask your supervisor or human resources department about available employee assistance programs. Don’t be afraid to seek help when you need it.

Suicide prevention: new resource from OSHA

In an effort to prevent suicides, OSHA has published a new resource that features tips on how to identify and respond to warning signs. “Suicide is a leading cause of death among working-age adults in the United States,” the agency says. “It deeply impacts workers, families, and communities.”

OSHA’s tips for helping to prevent suicide:

Everyone can help prevent suicide: “Mental health and suicide can be difficult to talk about – especially with work colleagues – but your actions can make a difference. When you work closely with others, you may sense when something is wrong.”

Know the warning signs: “There is no single cause for suicide, but there are warning signs. Changes in behavior, mood or even what they say may signal someone is at risk. Take these signs seriously. It could save a life.”

Ask “Are you OK?”: “If you’re concerned about a co-worker, talk with them privately and listen without judgment. Encourage them to reach out to your employee assistance program, the human resources department, or a mental health professional.”

If someone is in crisis, stay with them and get help: “If you believe a co-worker is at immediate risk of suicide, stay with them until you can get further help. Contact emergency services or the National Suicide Prevention Lifeline” at +1.800.273.TALK (8255).

OSHA highlights the American Foundation for Suicide Prevention as an additional resource for information on risk factors, warning signs and what you can do to help prevent suicide.

Source: Occupational Safety and Health Administration (OSHA) | osha.gov

ANSI/ISEA standard on workplace first aid kits gets update

To determine if additional first aid supplies are needed on a jobsite, consider the uniqueness of the work environment and the types of potential injuries.

The above suggestion is in the recently revised American National Standards Institute/International Safety Equipment Association standard Z308.1, which OSHA cites as a recommended, nonmandatory source of guidance for minimum first aid kit requirements. ANSI/ISEA Z308.1-2021 was approved April 15 and goes into effect October 15. The previous update took place in 2015.

“Of course, getting in compliance sooner [rather] than later is good because these changes are meant to improve safe outcomes for employees,” Todd VanHouten, chair of ISEA’s first aid product group, said during a May 12 webinar that explored changes to the standard.

Among the highlights:

More specificity for tourniquets: The equipment intended to prevent blood loss should be at least 1.5 inches wide and be effective for limb sizes 7-33 inches around.

Making foil blankets mandatory: This measure was enacted after assessing similar international standards and recognizing “the multiple purposes that the item can serve to respond to first aid emergencies.”

Further guidance on bleeding control kits: These “contain more advanced first aid supplies to immediately treat life-threatening external bleeding,” ISEA says.

Additionally, the revision includes a “more robust discussion” to assist employers when assessing risks and identifying potential hazards to select additional first aid supplies. The standard calls on employers to consider:

- What are the potential hazards?

- What kinds of injuries have occurred or could occur in relation to these hazards?

- What types of first aid supplies are needed to treat these injuries?

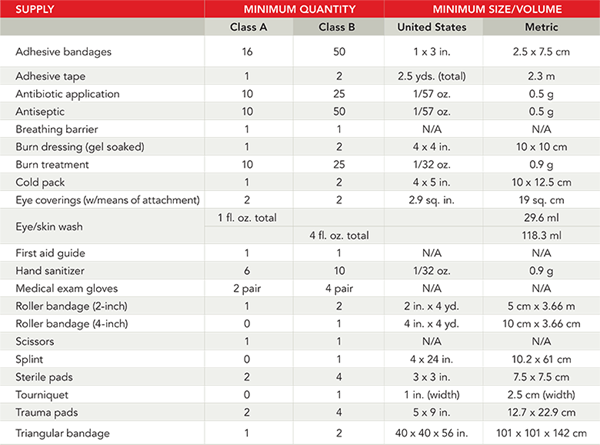

The revision retains the classification of “Class A” and “Class B” kits, introduced in the Z308.1-2015 update and based on the quantity and assortment of supplies. Class A kits generally are suitable for all wounds, minor burns, and eye injuries. Class B kits are intended to treat injuries more often found in densely populated workplaces with complex and/or high-risk environments, such as warehouses, factories, and outdoor areas.

“Employers should check their first aid cabinets against the new standard and make the necessary changes,” ISEA says. “In determining which class of kit is more appropriate for a given workplace, employers should conduct a workplace hazard assessment to first decide if a Class A or Class B minimum fill best fits the type of hazards at the facility.”

Employers are encouraged to inspect first aid kits “at least monthly” or “following a first aid incident when product is used,” and to disinfect cabinet surfaces regularly.

What supplies should be in my first aid kit?

A revision of the ANSI/ISEA standard, Z308.1-2015, took effect in June 2016 and introduced two classes of first aid kits. Identified as “Class A” and “Class B,” the kits are based on the quantity and assortment of supplies.

Class A kits generally are suitable for all wounds, minor burns, and eye injuries. Class B kits are designed to treat injuries more often found in densely populated workplaces with complex and/or high-risk environments, such as warehouses, factories, and outdoor areas.

Minimum kit requirements:

Kits in compliance with Z308.1-2015 feature supplies arranged in uniform, color-coded boxes to ease organization: blue for antiseptics, yellow for bandages, red for burn treatment, orange for personal protective equipment, and green for miscellaneous items. In addition, kits are organized into one of four types based on work environment:

- Type I: Containers are mountable and intended for stationary, indoor settings.

- Type II: Portable and intended for indoor use.

- Type III: Must be portable, mountable, and have a water-resistant seal.

- Type IV: Must be portable, mountable, and waterproof.

This "document” is intended for general information purposes and should not be construed as advice or opinions on any specific facts or circumstances. The content of this document is made available on an “as is” basis, without warranty of any kind. This document cannot be assumed to contain every acceptable safety and compliance procedure or that additional procedures might not be appropriate under the circumstances. Markel does not guarantee that this information is or can be relied on for compliance with any law or regulation, assurance against preventable losses, or freedom from legal liability. This publication is not intended to be legal, underwriting, or any other type of professional or technical advice. Persons requiring advice should consult an independent adviser or trained professional. Markel does not guarantee any particular outcome and makes no commitment to update any information herein, or remove any items that are no longer accurate or complete. Furthermore, Markel does not assume any liability to any person or organization for loss or damage caused by or resulting from any reliance placed on this content.

Markel® is a registered trademark of Markel Group Inc.

© 2023 Markel Service, Incorporated. All rights reserved.